Service Introduction

In Taiwan, the encouragement and expectations of renewable energy are increasing yearly, and the number of solar system installations has augmented by multiples. However, due to the physical stringing effect of solar power plants, once the current of a single module is lower than the average value of other modules, it will affect the power generation of the other 20-22 templates in the same string. Additionally, by reason of air pollution, salt damage, biogas, exhaust and drainage equipment, little chance of rain, etc., in the local environment, the dust, oil pollution, birds’ droppings, and biogas easily adhere to the panel, which reduces the power generation efficiency of the panel by 60~70%, and more likely to cause hot spots and snail textures in the templates. If the O&M contractors without professional training intentionally step on the templates during the cleaning process and cause the internal cracks in the module, or improperly scratch the surface of the templates with cleaning tools, it will greatly affect the overall power generation of the power plant.

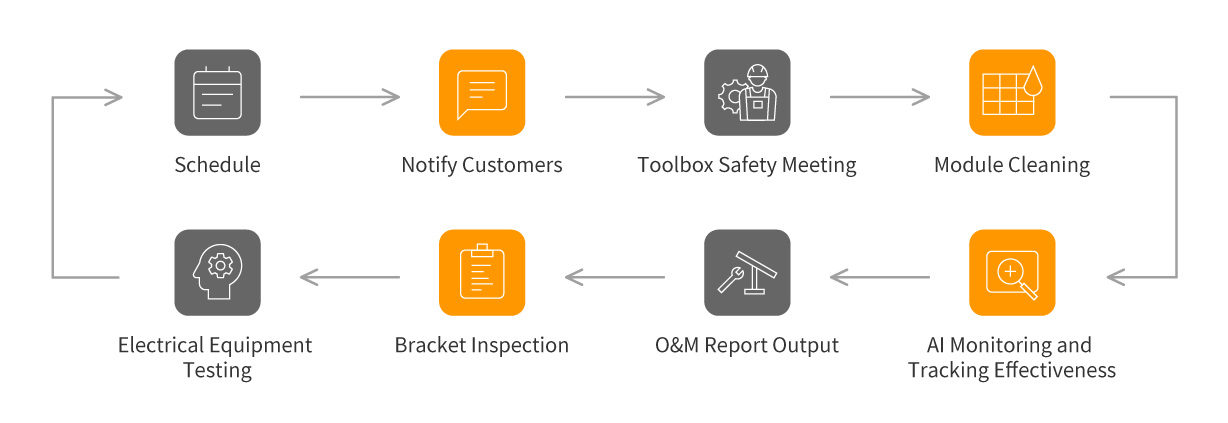

Service Process

From the initial construction of the solar power plant to the 20-year cost amortization, how to achieve the goal of the annual power generation efficiency as scheduled is major issue that Taiwan solar investment owners need to face and overcome. At the beginning of our establishment, Billion Watts took the professional power plant O&M as the company's foothold. We overcome the above difficulties one by one, find out the correct and efficient O&M methods, establish professional service quality control SOP, discuss various power plant maintenance methods and cycles with customers in a central management manner, and assist customers in reducing the burden of power plant management. When an abnormality is found, completing the repair in the shortest time can further reduce the economic loss caused by poor power generation. We work with solar power plant investors to achieve the ideal asset maintenance and risk reduction, implement the power generation benefit estimate and optimize the return on investment.